&

Case Study

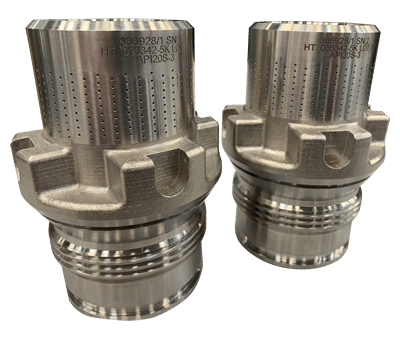

Industrial 3D-Printed Parts for Oil & Gas Field Service Applications

Keeping oil and gas production facilities running smoothly is never easy. Operators need a way to provide key replacement parts to facilities in distant corners of the world without stockpiling expensive inventory at every location or redesign and qualify a new part from scratch.

Download the case study to learn how IMI Critical Engineering leveraged the Velo3D fully integrated 3D metal printing solution to provide a major Oil & Gas operator with key replacement parts reliably and quickly.

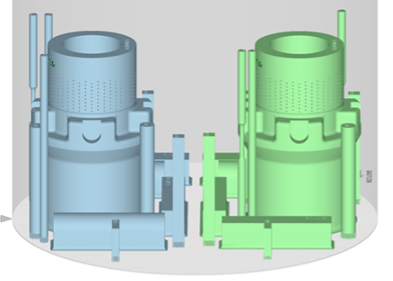

Two choke valves, optimized with IMI’s DRAG technology shown in Velo3D’s Flow software.

At a Glance

No redesign or Design for Additive Manufacturing (DfAM) required

Improved part performance

Improved maintenance and supply chain scalability

Do More and Go Further with Velo3D

Schedule a call with an expert to learn how Velo3D can transform your business and help solve your engineering challenges.