&

Case Study

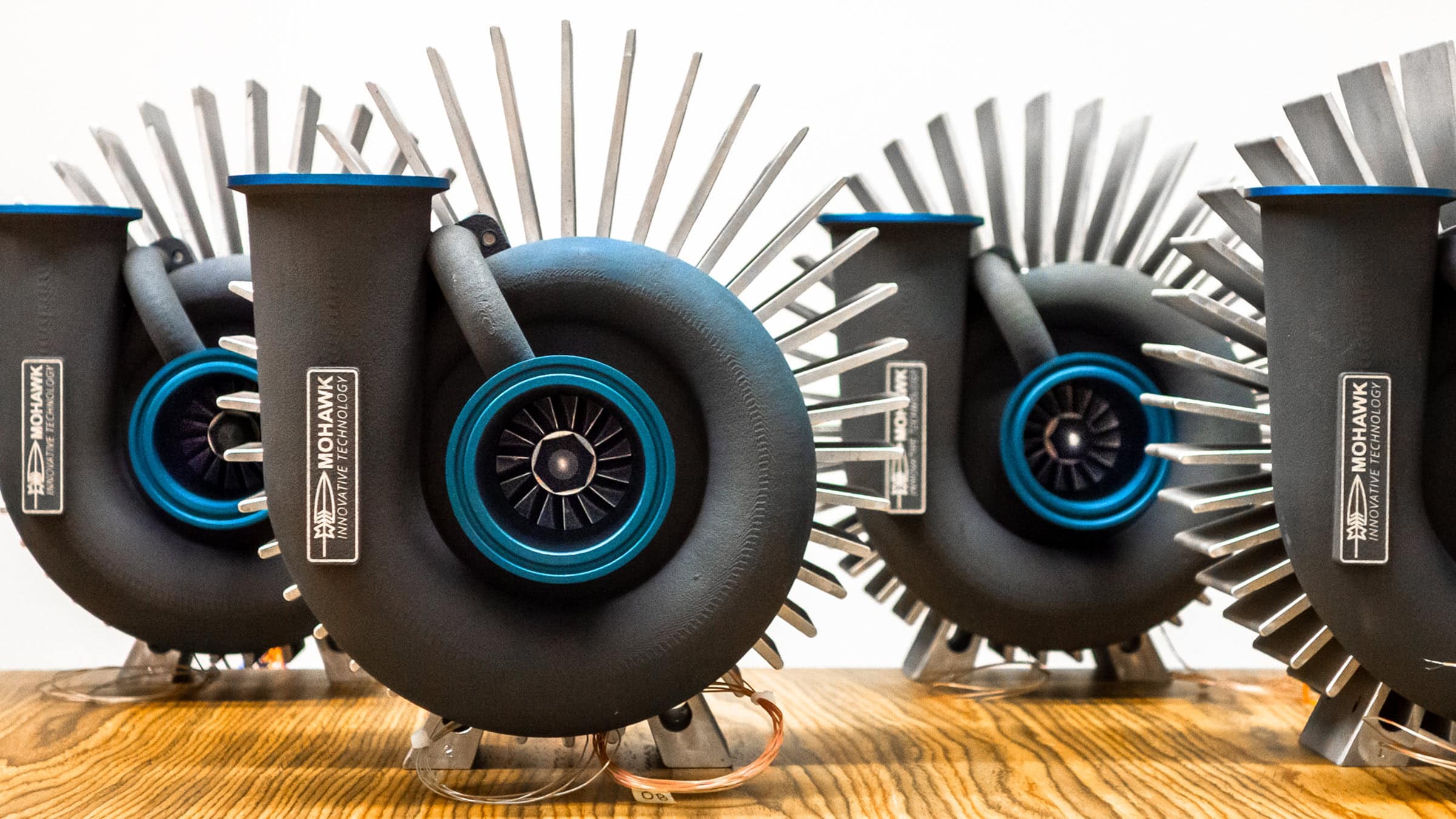

Mohawk Innovative Technology’s Exploration of Metal AM Transforms Part Efficiency and Durability All While Driving Down Costs

Working on programs in support of solid-oxide fuel cell (SOFC) technology funded by the US Department of Energy, Mohawk Innovative Technology was tasked with revamping the design and manufacturing of core parts of the SOFC stack—specifically Anode Offgas Recycle Blowers (AORB)—to be more cost effective and durable.

In this case study, discover how Mohawk accomplished both objectives by leveraging Velo3D’s advanced metal additive manufacturing technology as a reliable alternative to manufacturing turbomachinery components.

Oil-free Anode Offgas Recycle Blowers (AORB) made by Mohawk Innovative Technology Inc. (MITI).

At a Glance

How the Velo3D fully integrated metal AM solution enabled Mohawk to overcome significant design challenges inherent to high-speed centrifugal impellers with flexibility and ingenuity.

How Mohawk and Velo3D teams achieved the durability standards required of the project.

The cost reduction achieved using Velo3D metal AM versus traditional subtractively manufactured impeller wheels.

Do More and Go Further with Velo3D

Schedule a call with an expert to learn how Velo3D can transform your business and help solve your engineering challenges.