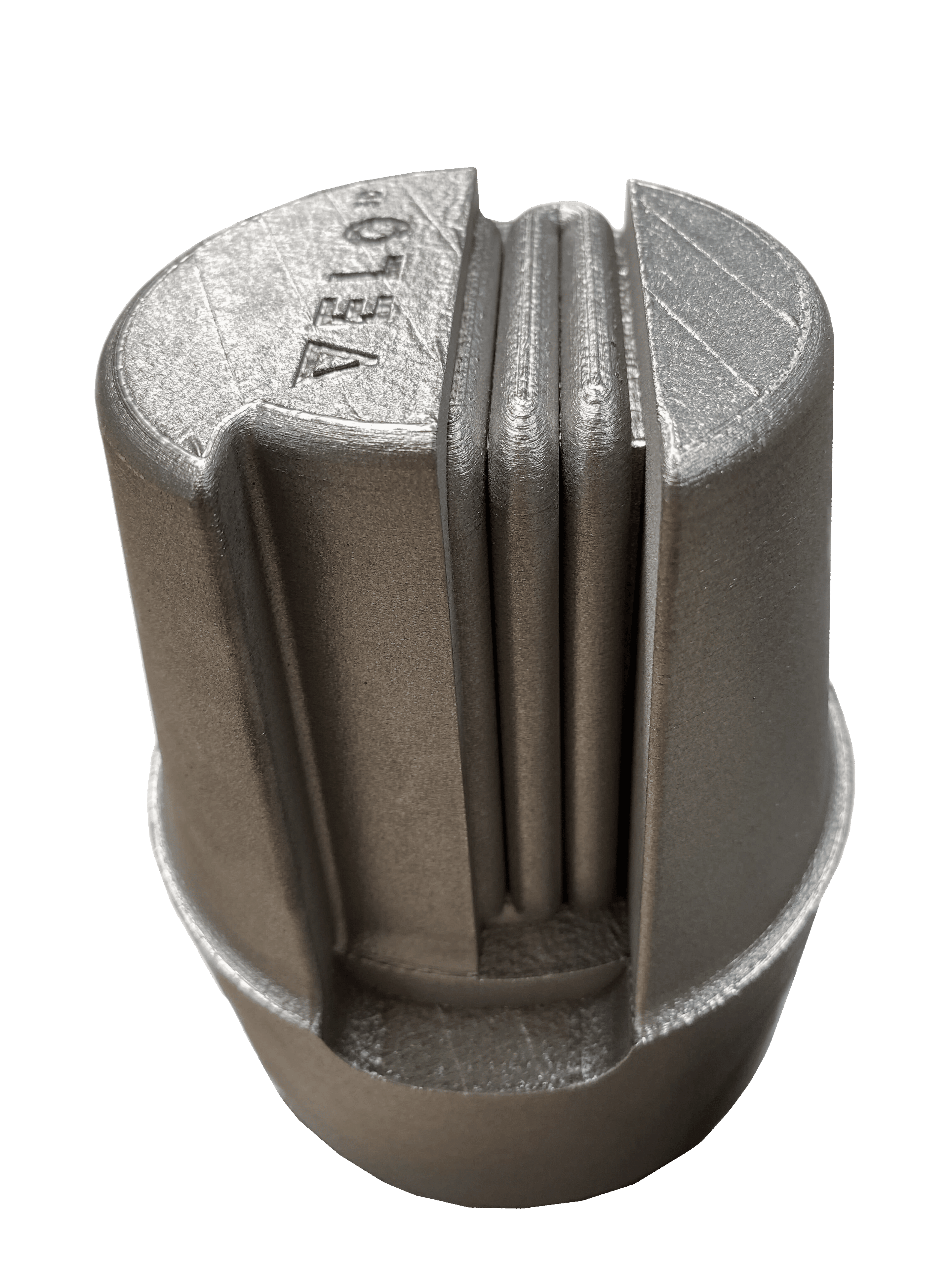

M300 Steel

Ideal for automotive tooling applications, such as High Pressure Die Cast (HPDC) inserts, tooling inserts, tire sipes & molds, & other high strength components.

Material & Process Capability

M300 Steel is an ultra-low carbon alloy with very high strength & hardness properties derived from intermetallic compounds rather than carbon content. The material is comprised mainly of nickel, with cobalt, molybdenum, & titanium as secondary intermetallic alloying metals.

It is ideal for tooling applications such as High Pressure Die Cast (HPDC) inserts, injection molding, and other types of tooling.

The Velo3D fully integrated manufacturing solution uniquely enables companies to build the parts they need without compromising design or quality – resulting in complex parts higher in performance than traditional casting techniques or other additive methods.

General Process

This data sheet specifies the expected mechanical properties and characteristics of this alloy when manufactured on a Velo3D Sapphire System. All data is based on parts built using Velo3D standard 50 μm layer thickness parameters, using Praxair FE-339-3, a Velo3D-approved powder. Parts built from M300 on a Sapphire System can be heat treated like those manufactured by other methods.

| Density, g/cc (lbs/cubic in) | 8.0 (0.29) |

| Relative Density, percent | 99.9+ |

| Surface Finish1, Sa, μm (μin) | <15 (590) |

Mechanical Properties at Room Temperature

| Property2 | Modulus of Elasticity, GPa (msi) | Ultimate Tensile Strength, MPa (ksi) | Yield (0.2% Off set), MPa (ksi) | Elongation At Break, percent | Charpy V-notch, J6 | Hardness, HRBW | ||||||||

| Process Recipe | TBR (cc/h)3 | Mean -3σ | Mean | Mean -3σ | Mean | Mean -3σ | Mean | Mean -3σ | Mean | Mean -3σ | Mean | Mean -3σ | Mean | |

| 1kW/50 μm | 45 | As Printed | 130 (19) | 105 (15) | 1015 (147) | 995 (144) | 800 (116) | 780 (113) | 18 | 14 | 44 | 31 | 29 | 25 |

| After Heat Treatment4 | 170 (25) | 160 (23) | 1490 (216) | 1470 (213) | 1280 (186) | 1265 (184) | 15 | 12 | 11 | 8 | 43 | 40 | ||

| After HIP5 | 168 (24) | 157 (23) | 1430 (207) | 1380 (200) | 1195 (173) | 1115 (162) | 18 | 11 | 24 | 20 | 46 | 45 | ||

| 1. Depends on orientation and process selected; for angles >25° from horizontal. 2. All specimens were printed in argon atmosphere and tested using ASTM E8/E8M-22, ASTM E23-18, or ASTM E18-22. Mechanical & tensile samples printed in vertical orientation, machined to ASTM E8 (round specimen #3). 3. TBR: Theoretical Build Rate (TBR) is a per-laser build rate calculated from the process conditions of bulk core as scan speed x hatch spacing x layer thickness. This value represents a single laser only and is reported for comparison purposes across different materials and recipes, but does not correspond to true build rate, which is dependent on geometry and system characteristics (i.e. number of lasers, recoat times, etc.). 4. Solution at 850°C, 2 hours and age 600°C, 6 hours. 5. Solution at 850°C, 2 hours and age 630°C, 1 hour. 6. Charpy blocks were printed in the XY direction and machined. | ||||||||||||||

Qualified Powder Suppliers

DS-M300.EN.2024-03-15.v-0-31.U.USL 0905-26166_A 2024-03-15. Specifications are subject to change without notice. ©2024 Velo3D, Inc. All rights reserved. Velo, Velo3D, Sapphire, and Intelligent Fusion are registered US trademarks and Assure, Flow, and Without Compromise are trademarks of Velo3D, Inc. All other product or company names may be trademarks and/or registered trademarks of their respective owners.