Leading Provider of Metal 3D Printing Solutions

Velo3D’s advanced, fully integrated metal additive manufacturing solution helps engineers build the complex, mission-critical parts they need without compromising design, quality, or performance.

Trusted by Today’s Most Innovative Companies

State-of-the-Art Manufacturing for Mission Critical Parts

Design Freedom

Unleash your imagination, reimagine what’s possible, and unlock previously impossible designs with the world’s most advanced additive manufacturing solution available.

Quality Assurance

Our integrated push button calibration and onboard metrology, featuring ~1,000 different sensors, tracks the behavior of the machines before and during the print to give you confidence in the quality of your parts.

Agility

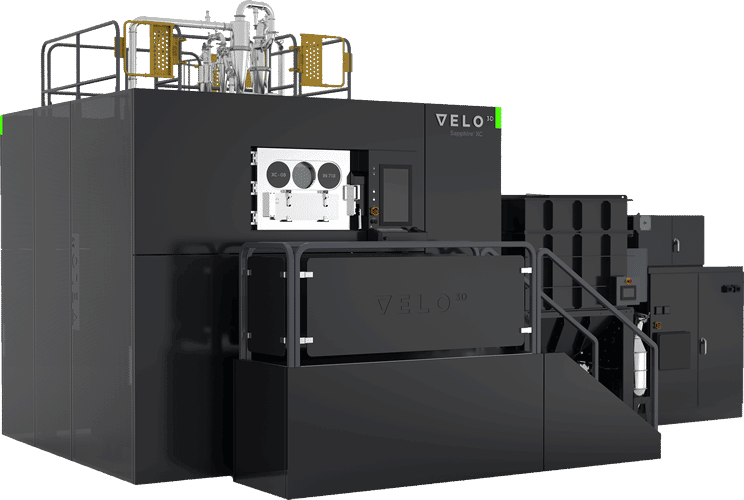

Leverage our network of contract manufacturing (CM) partners or operate your own Velo3D manufacturing solution to produce your designs at scale through a distributed supply chain. With Velo3D’s golden print file, your part can be reproduced from a single software file with matching accuracy, material properties, and quality control on any matching Sapphire printer.

Enhanced Efficiency

Fully Integrated Metal AM Solution

Flow Software

Flow print preparation software is responsible for prescribing the manufacturing process for the Sapphire family of metal 3D printers. With Flow, engineers can analyze their parts and apply the right solution for each feature. Flow now includes user-selectable core parameter sets that provide enhanced control over builds with the ability to assign different core instructions to parts within the same build.

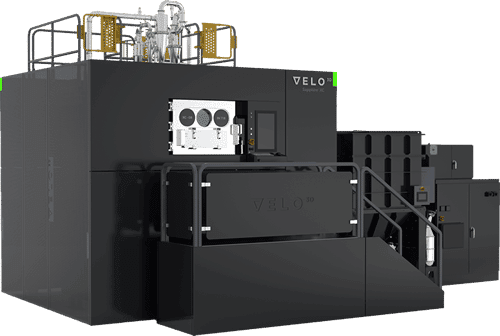

Sapphire Family of Metal AM Printers

Assure Software

Underlying Manufacturing Process

Velo3D’s highly intelligent processes bind print preparation software, advanced metal printer patented technology, and quality assurance software into a complete manufacturing solution by intelligently managing the information flow, sensor data, and the advanced printing technology for precision control of the entire process for multiple mission-critical industries.

Manufacturing Process

Unlock Your Innovation

Velo3D enables next-generation innovation. Check out our latest high-value assets and discover how we’re helping push manufacturing into a new era of capability, without compromise.

Introducing Flow Developer!

Flow Developer empowers engineers to optimize processes by transferring or creating parameter sets in Flow, eliminating project restarts. This grants access to Sapphire printers’ control and quality for achieving program goals. Users gain flexibility, visibility, and control within one software platform.